A Single-Stage Offline LED Driver for Incandescent Replacement

Contributo di Convergence Promotions LLC

2011-05-27

A single-stage, high power factor, offline buck converter can provide a simple, small, and low-cost driver for LED lamps. This article explains how it’s done.

LED lighting offers many potential benefits over incandescent, halogen, fluorescent, and gas/arc lamps. It has a longer life, is more efficient, and has no mercury. With the banning of incandescent lamps in Europe and Canada, and soon in the US, LED lamps are gaining more interest.

To achieve a high power factor, one could use either passive power factor correction (PFC) or active PFC. Typically, the passive PFC solution requires large passive components making it difficult to fit the small size of a lamp’s socket. The traditional active PFC circuit requires a two stage topology, e.g., a boost stage for PFC, then a buck or flyback stage for the current regulation of the LEDs. Obviously, the cost of two stages is high, and the size is too big. To increase efficiency and reduce the size of the circuit, a non-isolated topology should be used.

In this article a single-stage, high power factor, non-isolated, offline buck converter is introduced for LED lamps. The buck converter is chosen for this application due to its simplicity, small size, and low cost. The converter operates with constant peak current and in transition mode (boundary mode between CCM and DCM) to achieve soft switching. A high power factor is achieved by reshaping the peak current near where the input AC line is close to the output LED voltage.

Proposed circuit

Figure 1 shows the proposed single-stage buck LED driver. The converter operates in transition mode; sometimes it is referred to as the boundary mode between continuous mode and discontinuous mode. If the inductor current is in the boundary mode, the average LED current is exactly half of the peak inductor current. If the peak current of the inductor is maintained, the LED current is well-regulated without needing to sense the LED current, which greatly simplifies the circuit design. Since the converter is operated in transition mode, the MOSFET is turned on at zero current and there is no reverse recovery current for the free-wheeling diode. This makes it beneficial for both EMI and efficiency.

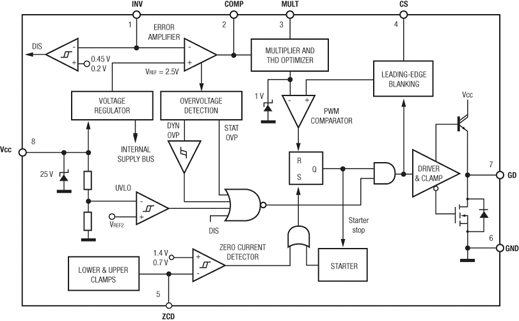

If the inductor current is constant, the power factor of the circuit will be very poor and the input current waveform will be significantly distorted during zero crossing (the input AC voltage is close to the output LED voltage). If there is a way to reduce the current amplitude near the zero crossing, the power factor can be improved. A transition mode PFC controller L6562A is used to achieve this. The L6562A is a current mode PFC controller operating in transition mode (boundary mode between CCM and DCM). Its linear multiplier enables the converter to shape the AC input current waveform following the input voltage. A block diagram of the L6562A is shown in Figure 2.

Near zero crossing, the multiplier function of the controller will effectively reduce the inductor current. For the rest of the time, the inductor peak current is kept constant at a designated level to maintain a constant LED current.

The following equations need to be considered in the design procedure and the operation of the circuit:

The input voltage: Vin(θ)= √2 * Vin * sin(θ) , Vin=120 VAC The output voltage: 9 LEDs in series, Vout 30 V The output current: Iout=350 mA

The design variable is the peak current of the inductor, Ipk, and the inductance is L.

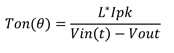

When Q1 is turned on, the inductor will be charged to Ipk. The on time will be:

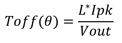

The off time will be:

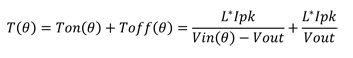

The period of the switching cycle will be:

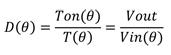

The duty cycle D will be:

The switching will happen when Vin>Vout.

The frequency is:

The switching frequency will vary during the line cycle, which is good for EMI because it spreads the spectrum.

The max frequency happens at peak input voltage:

Ipk will be 700 mA if it is an ideal condition. The actual peak value will be higher than this value since there is a dead time when the input voltage is lower than the LED voltage and the peak current is reduced near the period when the input line voltage is close to the LED voltage. If we choose the maximum switching frequency of ƒsw max to be less than 150 KHz, from the equation above, we can have:

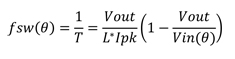

The operation of the converter is as follows:

The period of t0 to t1 is when the input voltage is lower than the LED voltage. During [t0,t1], there is no inductor current since the input voltage is lower than the LED voltage.

The period of t1 to t3 is when the input voltage is higher than the LED voltage, but they are close. During [t1,t2], Q1 is turned on at time t1. The inductor current reaches the peak at t1. During this period, the peak amplitude will be lower than the constant value, Ipk. The peak value is determined by the multiplier input.

During [t2,t3] , Q1 is turned off at t2. The inductor current will decrease to zero at t3. At time t3, the ZCD pin of the controller will detect the ZCD signal as being low and turn on Q1 again at t3. Q1 is turned on at zero voltage, and there is no diode reverse recovery problem for a free-wheeling diode. The coupled winding of the inductor provides the ZCD signal.

The period of t4 to t6 is around peak line voltage. During [t4,t5], Q1 is turned on at time t4. The inductor current reaches the peak at t4. The peak amplitude is the pre-defined constant value, Ipk. During [t5,t6], Q1 is turned off at t5. The inductor current will decrease to zero at t6. At time t6, the ZCD pin of the controller will detect the ZCD signal as being low and turn on Q1 again.

The LED will see 120 Hz ripple. An output filter capacitor, Cout, is necessary to reduce the ripple down to the required value.

Test results

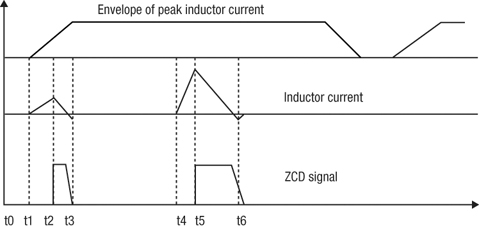

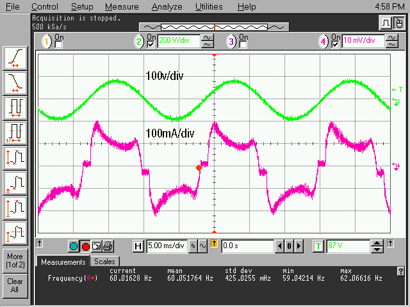

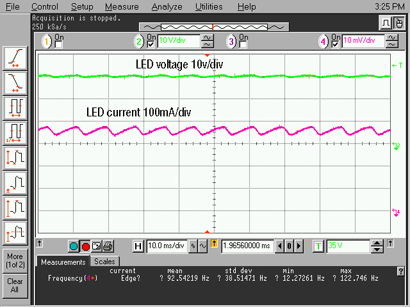

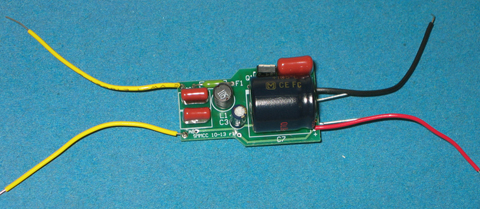

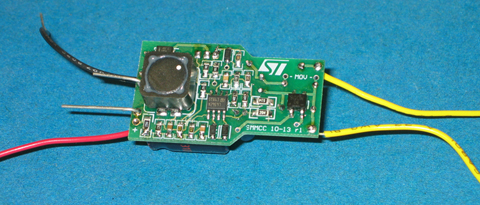

Figure 4 shows the input current waveform with the proposed power factor correction. The input power factor is higher than 0.88. The efficiency of the converter is higher than 89 percent. Figure 5 shows the inductor current envelope versus input voltage, Figure 6 shows the LED voltage and current, and Figure 7 shows the final board.

For circuit detail and BOM, please refer to STMicroelectronics Application Note 3256.

Running at transition mode provides the benefit of lowering the switching loss and reducing the spread of the EMI spectrum. The buck converter achieves the LED constant current by operating at inductor constant peak current without LED current sensing, and high power factor is achieved by reshaping the current waveform when the input line voltage is near the output LED voltage. This solution is simple, of low cost and small size, and suitable for an incandescent replacement application.

References:

- In-Hwan Oh, “A Single-Stage Power Converter for a Large Screen LCD Back-Lighting,” APEC 2006.

- Datasheet of the L6562A, STMicroelectronics.

- Shao, Jianwen, “Single Stage Offline LED Driver,” APEC 2009.

- STMicroelectronics Application Note AN3256

Esonero della responsabilità: le opinioni, le convinzioni e i punti di vista espressi dai vari autori e/o dai partecipanti al forum su questo sito Web non riflettono necessariamente le opinioni, le convinzioni e i punti di vista di DigiKey o le sue politiche.